Jig Grinding

Bedestone specialise in Conventional / CNC Jig Grinding and has over 40 years experience in providing precision grinding to a number of businesses and industries across Birmingham and the UK.

With over 200 years of cumulative experience within our team, and with all work completed in a contained temperature controlled environment, we are able to guarantee unparalleled accuracy in all of our Jig Grinding.

We have vast experience carrying out jig grinding for a variety of industries, including Aerospace, Nuclear and Formula 1 and Motorsport, and have built a strong reputation as industry leaders in grinding services.

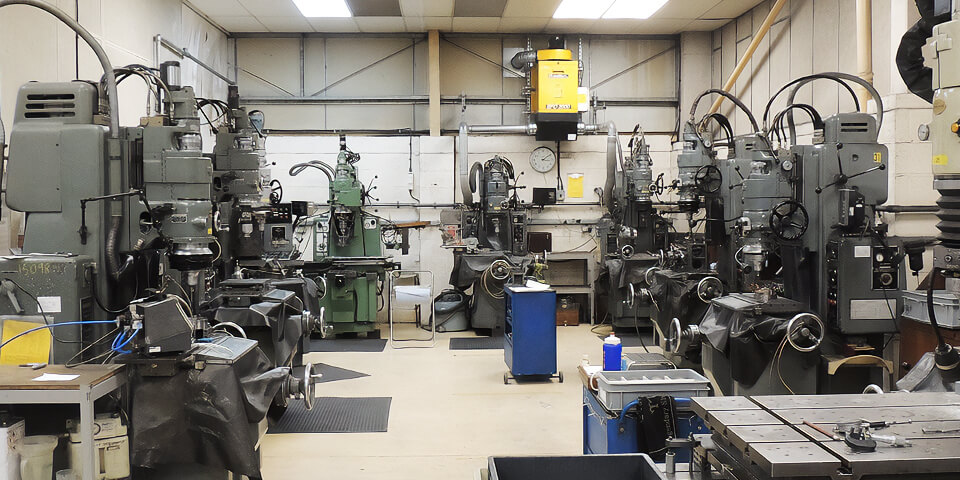

We are able to offer the sub-contract facilities of 16 jig grinders, of which 6 are CNC controlled, making us the largest sub-contract jig grinding operation in the UK.

Contact us today to find out how we can provide your businesses with the highest quality Conventional / CNC Jig Grinding in Birmingham.

Machines

CNC Jig Grinding

- S35 Hauser (500x300mm)

- 1200 Moore (1200x600mm)

- 3x G48 Moore (1200x600mm)

- G18-8400 Moore(450x280mm)

(The Moore machines have CNC Rotary Indexing Tables with a 2” second accuracy capability)

Manual Jig Grinding

- 6x No.3 G18’s (450x280mm)

- 3x No.2 (420x260mm)

- No.3 High rise(450x280mm)

- No.2 High rise(420x260mm)

Universal Grinder

- Jones & Shipman 1307 (Ø350mm)

Ancillary Equipment

- 9 x Moore Spin Tables

- 6 x Moore Sine Tables

- 5 x Moore Rotary Tables

- 2 x Moore High Precision

- Programmable Rotary Tables

- 1 x Moore High Precision Rotary Table

- 4 x Moore Angle Plates

- 10:1 Diaform